Frequency Converters (VFDs): A Complete Guide to Saving Money and Preventing Breakdowns

Frequency converters, also known as VFDs, have become an essential tool in modern industry. They allow for the efficient control of electric motors, which results in energy savings of up to 60% and extended equipment life. But this magic disappears if the converter is poorly designed or installed. Improper implementation can lead to failures, motor overheating, and severe electromagnetic interference.

This article will walk you through three key phases to ensure your VFD system operates optimally, efficiently, and reliably for years to come.

Phase 1: Careful Design – Choosing the Right One

Before any physical installation, you must conduct a thorough analysis. A poor choice in this phase can cause a lot of problems down the road.

Application and Load Analysis

A converter's behavior fundamentally differs based on the type of load. You must answer a basic question: What will the motor be used for?

Constant Torque: The motor must deliver a constant torque even at low speeds. This is typical for conveyors, lifts, cranes, or presses. Here, you need a converter with a higher overload capacity (usually 150-200% of the rated current).

Variable Torque: The required power and torque increase with the square of the speed. This is typical for pumps and fans. Here, a standard converter is often sufficient, even from the more cost-effective series specifically designed for these applications (often labeled "pump/fan").

Proper Sizing

Selecting a converter by the motor's power (kW) is only a first estimate. It's far more accurate to size it by the converter's rated output current (Iᵥᵥₜ). This value must be greater than or equal to the motor's rated current (Iₘ). For demanding applications with frequent starts, we recommend choosing a converter one size larger in terms of power. Also, remember to consider operating conditions such as high ambient temperatures or altitudes, which reduce the converter's cooling capacity.

Essential Accessories and Protections

To ensure a long and trouble-free life for the entire system, consider investing in these components:

AC Line Reactor: On the input, it protects the converter from voltage spikes and grid distortions, which significantly extends its lifespan.

Motor Reactor: On the output, it protects the motor from rapid voltage rises (dV/dt) caused by modern converter technology. It's a necessity for longer cable runs (>50 m).

EMC Filter: It limits the high-frequency interference that the converter emits into the power grid. This is often mandatory in residential areas or where sensitive electronics are present.

Braking Resistor and Module: Essential for applications with frequent and rapid braking of a heavy load (e.g., elevators), where the motor acts as a generator and sends energy back to the converter.

Phase 2: Thorough Installation – Preparation Is Half the Battle

Poor installation is one of the most common causes of premature failures. Prevent them with careful preparation.

Choosing the Right Location

A converter generates heat and is sensitive to its environment. Choose a location that is:

Clean and well-ventilated: Avoid dusty, humid environments or areas with aggressive chemicals.

Spacious: Maintain minimum distances from other equipment and walls (at least 100 mm) to allow the converter enough room for air circulation and effective cooling.

Accessible: Ensure easy access for maintenance, adjustments, and diagnostics.

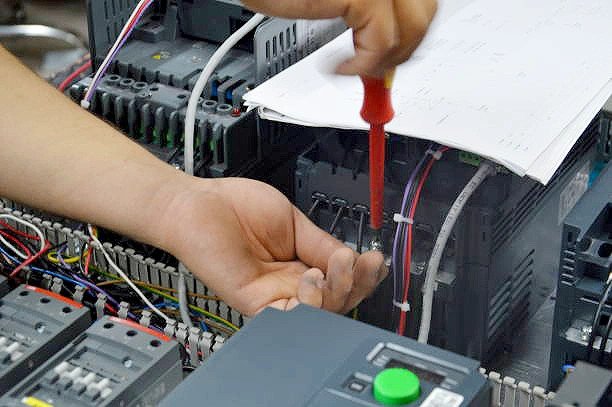

Electrical Wiring and Safety

There are no compromises here.

DISCONNECT POWER! Always perform all work on disconnected equipment.

Grounding: Proper grounding is an absolute necessity. Use a dedicated grounding terminal and an adequately sized cable. Poor grounding is a source of interference and instability.

Cabling: Use cables with the correct cross-section for the main power and the motor. The Golden Rule: Always run the motor output cables separately from the control and signal cables. This strict separation is the most effective defense against electromagnetic interference (EMI). Always use shielded cables for signal and control wiring.

Phase 3: Commissioning & Maintenance – Fine-Tuning

Once the physical installation is complete, it's time to focus on the "soul" of the entire system and its longevity.

Commissioning

Enter Motor Parameters: Before the first start, it is mandatory to enter the motor's parameters from its nameplate (voltage, current, frequency, power).

Autotune: We highly recommend using this function. The converter will measure the motor's electrical parameters and optimize its control algorithm, which ensures smoother operation and higher efficiency.

Ramp Settings: Set the acceleration and deceleration times reasonably. Times that are too short can cause an overload at startup or trigger protection during stopping.

First Start: First, perform a test without a mechanical load. Gradually increase the speed and check that the motor runs quietly, without vibrations, and in the correct direction.

Regular Maintenance

Even the best installation requires care.

Monthly Checks: Visually inspect for cleanliness, tightness of connections, and any signs of overheating.

Quarterly Cleaning: Regularly remove dust from the cooling fins and fans. A blocked heatsink is a common cause of failure.

Replacing Wearable Parts: Plan for the preventive replacement of fans (usually every 5-7 years) and check DC link capacitors (after 8-10 years) according to the manufacturer's recommendations.

Backing up Settings: Remember to back up the converter's settings. This will save you hours of work if you ever need to replace it.

Quick Diagnostics: Common Error Codes and Their Solutions

Even with the best installation, a converter might stop and display an error code. This doesn't always mean a disaster. Here is a quick overview of the most common issues and their possible causes, which will help you with initial diagnostics.

Important: Before handling anything, always turn off the power first and ensure the equipment is in a safe state!

Overvoltage: This error code appears when the voltage in the VFD's internal DC bus exceeds the allowed limit. It most often happens during rapid motor deceleration, where the motor acts as a generator.

What to do: Check deceleration times or consider installing a braking resistor.

Overcurrent: This error indicates that the converter is supplying too high a current to the motor. Common causes include a mechanical overload on the motor, a short circuit on the output, or an excessively short acceleration time.

What to do: Relieve the mechanical load, lengthen the acceleration time, or check the motor cables.

Overheating: This protection activates if the converter's internal temperature exceeds a set limit. Causes can include poor ventilation in the cabinet, clogged cooling fins, or a non-functional fan.

What to do: Clean the cooling system, ensure sufficient airflow, and check the fan's functionality.

Ground Fault: The code appears if a current leak to the ground is detected, typically on the output to the motor.

What to do: Check the motor, the motor cables, and their insulation for any damage.

Undervoltage: The converter detects a drop in the input voltage below the allowed limit. This can be caused by a voltage dip in the grid or an overload on the input circuit.

What to do: Check the power supply and circuit breakers.

| Fault (Typical Code) | What it means | Most Common Causes | First Things to Check |

|---|---|---|---|

| DC Bus Overvoltage (OV, Overvoltage) |

The voltage in the drive's internal DC bus has exceeded the allowed limit. |

|

|

| Overcurrent (OC, Overcurrent) |

The drive is supplying more current to the motor than is allowed. |

|

|

| Overheating (OH, Overtemp) |

The drive's internal temperature is dangerously high. |

|

|

| Ground Fault (GF, Earth Fault) |

The drive has detected a current leak to earth ground on the output. |

|

|

| Undervoltage (UV, Undervoltage) |

The input network voltage has dropped below the permissible level. |

|

|

Important: This overview is for quick orientation. The user manual for your specific drive model is always the most important source of information. Always disconnect power first and ensure the equipment is in a safe state before any troubleshooting!

Don't Rush It, It Will Pay Off

A well-designed and installed frequency converter is a quiet, efficient, and above all, reliable partner. And even if it occasionally shows an error code, knowing the most common causes will help you quickly get it back online with minimal downtime.